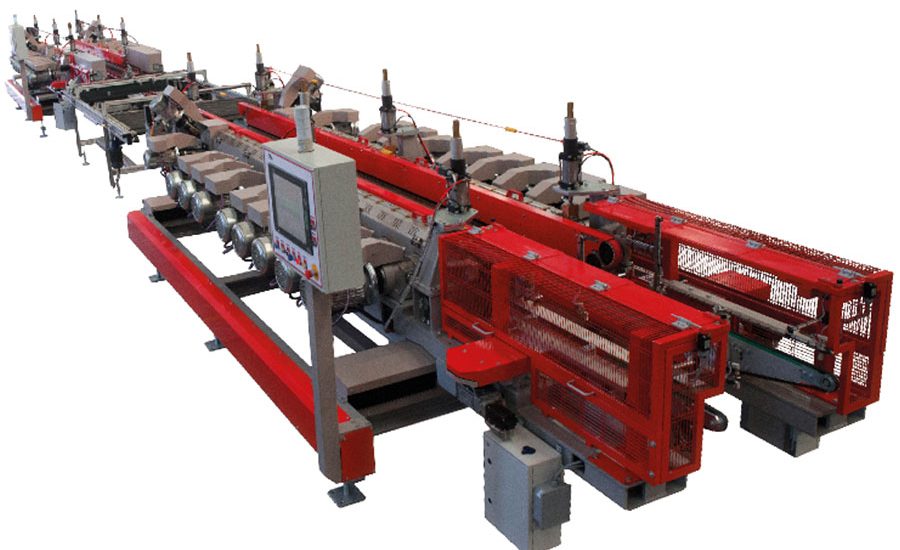

The new dry squaring line Dry Square 100-1500 is composed of two modules performing the 90° squaring and bevel chamfering on porcelain gres tiles.

Each module is completely controlled by PLC automation for the adjustment of the drive motors, the centering and squaring devices as well as the spindles positioning.

The new squaring machines have the following innovative characteristics:

- Usage of HIGH ROTATION SPEED CALIBRATING SPINDLES with SCT technology (Small Chip Thickness). The technology developed by Tecnema allows to use a lower number of calibrating spindles in comparison to the competitors (with the same production capacity), and grants at the same time an higher reliability and lifetime of the whole spindles on the machine. As a consequence the maintenance costs as well as the management costs of the line are drastically reduced.

- AUTOMATIC RECOVERY OF THE WHEELS WEAR controlled by PLC or by smart-phone application.

- AUTOMATIC 90° SQUARING POSITIONING managed electronically from the control panel of the machine or by the size control system at the end of the squaring line: the diagonal control and the machine adjustment is performed automatically with absolute precision thanks to the independent pushing system patented by Tecnema.

Dry Square grants to its users several additional advantages in terms of productivity, economy and environmental sustainability.

The squaring machines have a standard of 8+8 calibrating spindles with 5,5 kW power motors (with the possibility of increasing this number up to 10+10 for additional removal power) for a total amount of 32 calibrating spindles on the whole line, a lower number in comparison to the 44-48 spindles used by our competitors, with an overall energy saving of approx. 100 kW of installed electrical power

Dry Square uses only diamond metal tools with a consequent overall reduction of the tools management costs. The incidence of the tools cost is furthermore enhanced by the SCT technology which increases the lifetime of each single wheel and at the same time reduces the heat generation within the contact zone between the material and the tool surface. The efficiency are 1,5 higher in comparison to the competitors and the Dry Square machine is capable of removing up to 8-10 mm per side by using only 8+8 calibrating spindle per module.

A key innovation is also represented by the automatic wheels wear recovery system which allows the operator within the push of a button to adjust all the wheels to their optimal working point, by resetting their working position and granting at the same time an uniform and constant processing on all the calibrating spindles.

Production costs are lowered up to 30% in comparison to the dry-squaring machines of the competitors.

In comparison to the traditional wet processing lines with an higher number of calibrating spindles, the maintenance costs on the line are reduced up to 50%. This is due to the absence of corrosive phenomena by working dry, avoiding salty fogs that could harm the machine’s components. Within the dry manufacturing the waste disposal costs are also cut down to the bottom, thanks to the lower specific weight of the dusts and to their complete recovery within the tiles production cycle.

After several years of work and improvement on squaring machines technologies, the Tecnema team has reached today its peak within the end line ceramic tiles processing industry, by proposing to its customers a complete package and by imposing a new quality standard to the industry.

The goal for the company is clear and simple: keep on pushing the development of innovative technologies to customers with the highest expectations.

The trust gained from top players in the industry, ready to heavily invest into innovation such as the Marazzi Group, has been for us an important springpad and represents at the same time a first class showcase for our product, as well as an extraordinary impulse for the future development of the company.