With 800 kW of installed power, the dryer can operate at full capacity using the energy from the factory’s photovoltaic roof. Key advantages include the ability to operate in ‘hybrid’ electric-gas mode, ensuring continuity of production at all times

On World Energy Efficiency Day, Primus Ceramics inaugurates – together with SACMI – the first ceramic dryer to be 100% powered using electricity generated from renewable sources.

Founded in 1969 and a SACMI partner since 2008 when the first complete line was installed (4 million m2 of tiles per year, 75% earmarked for export), Primus Ceramics has a growth strategy centered on quality, efficiency and environment-friendliness.

Hence their construction of the photovoltaic roof at the Aveiro plant, completed in 2020, and their request that SACMI modify the existing 5-tier ECP dryer to allow full-capacity operation using the electricity produced by the sun.

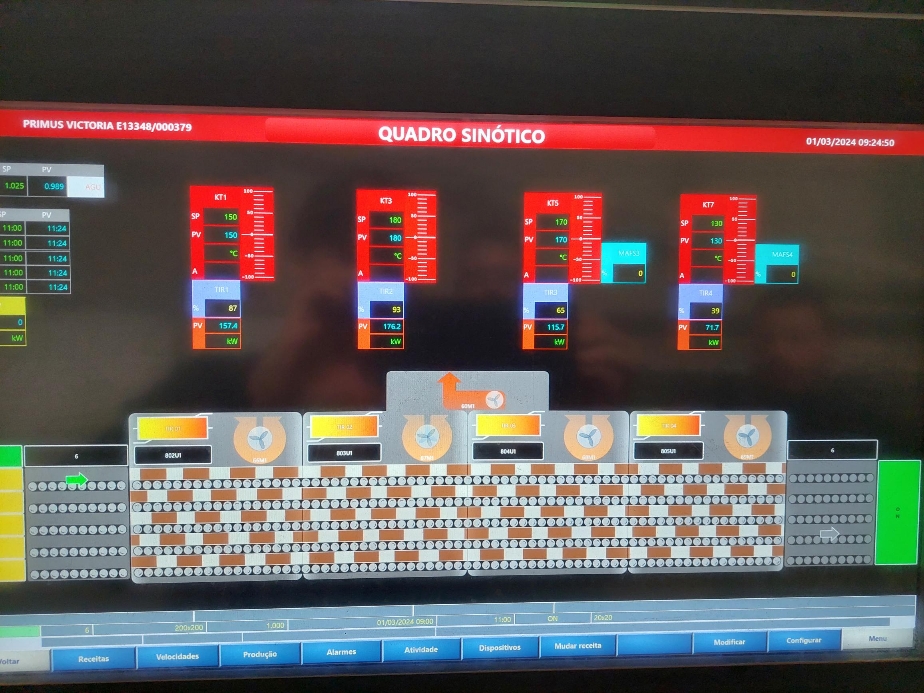

To achieve this, SACMI equipped the 4 dryer modules with suitable heating elements with a total installed power of 800 kW: enough to run the machine at full capacity without using traditional fuel. To achieve its new sustainability targets, the customer expanded solar panel coverage on the factory roof: the system now generates 2 GWh annually, preventing the release of 1,000 tons/eq of CO₂ into the atmosphere every year.

The key strength of the thus-reconfigured dryer is that it can operate both in full electric mode, in gas mode or in ‘hybrid’ mode (e.g. two electric modules + two gas modules) when less solar energy is available. In short, a machine equipped to ensure continuity of production at all times.

SACMI’s expertise offers the further advantage of being able to modify the existing machine without altering the plant layout. Replicable on a large scale, this solution allows SACMI – following its successful experience with Primus Ceramics – to offer the ceramic industry further decarbonization opportunitiesOn World Energy Efficiency Day, Primus Ceramics inaugurates – together with SACMI – the first ceramic dryer to be 100% powered using electricity generated from renewable sources.

Founded in 1969 and a SACMI partner since 2008 when the first complete line was installed (4 million m2 of tiles per year, 75% earmarked for export), Primus Ceramics has a growth strategy centered on quality, efficiency and environment-friendliness.

Hence their construction of the photovoltaic roof at the Aveiro plant, completed in 2020, and their request that SACMI modify the existing 5-tier ECP dryer to allow full-capacity operation using the electricity produced by the sun.

To achieve this, SACMI equipped the 4 dryer modules with suitable heating elements with a total installed power of 800 kW: enough to run the machine at full capacity without using traditional fuel. To achieve its new sustainability targets, the customer expanded solar panel coverage on the factory roof: the system now generates 2 GWh annually, preventing the release of 1,000 tons/eq of CO₂ into the atmosphere every year.

The key strength of the thus-reconfigured dryer is that it can operate both in full electric mode, in gas mode or in ‘hybrid’ mode (e.g. two electric modules + two gas modules) when less solar energy is available. In short, a machine equipped to ensure continuity of production at all times.

SACMI’s expertise offers the further advantage of being able to modify the existing machine without altering the plant layout. Replicable on a large scale, this solution allows SACMI – following its successful experience with Primus Ceramics – to offer the ceramic industry further decarbonization opportunities