Increasing aesthetic requirements, together with new plant technologies, have shifted the target of leading Italian ceramics producers towards increasingly large formats and towards achieving more elaborate and refined surfaces.

Increasing aesthetic requirements, together with new plant technologies, have shifted the target of leading Italian ceramics producers towards increasingly large formats and towards achieving more elaborate and refined surfaces.

Polished technical materials, such as glazed and subsequently lapped materials, today represent the majority of production for almost all operators in the ceramics industry, making the surface finish and technical performance fundamental aspects which are impossible to ignore.

ZSCHIMMER & SCHWARZ, always working alongside its customers to solve any technical-production issues, today presents POLISHIELD, the new range of end-of-line protective products.

Created from the synergy between the different ZSCHIMMER & SCHWARZ international locations, the POLISHIELD range brings together the ceramics know-how of the Italian ZSCHIMMER & SCHWARZ CERAMCO facility with the international skills of the other subsidiaries of the Z&S group, specialising in different chemical sectors, and offers a true innovation in the field of surface protection.

Industrial tests conducted at customer facilities, where POLISHIELD products were compared with the leading reference products on the market, showed performances of significant importance.

The development of the POLISHIELD 2395 (single application treatment) and POLISHIELD 364 (post-acid etching treatment) products are just the start of the path being followed by ZSCHIMMER & SCHWARZ to create the range.

As part of this development, a new working group was set up in ZSCHIMMER & SCHWARZ CERAMCO, completely dedicated to the subject. This group has access to a modern laboratory equipped with the most sophisticated equipment available on the market.

In line with the company philosophy which has always marked out ZSCHIMMER & SCHWARZ, this facility is available to its customers to study custom products developed to meet all of their production needs.

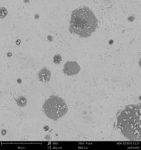

From the SEM photograph sequence produced within the ZSCHIMMER & SCHWARZ CERAMCO laboratories, it is easy to see the POLISHIELD filling mechanism at work, with filling of the porosity left open by polishing.

A comparison between the open pore of an untreated product (Fig. a) and the perfectly filled pore by POLISHIELD (Fig. B) is evidence of the effectiveness in preventing stains and dirt deposits.