The ecologic transition according to Italforni: between existing technologies, hydrogen, and hybrid solutions

The European and national policies regarding the reduction of environmental impact were not born with the recent and ambitious European Green Deal, but they make their first moves since from 90’s.

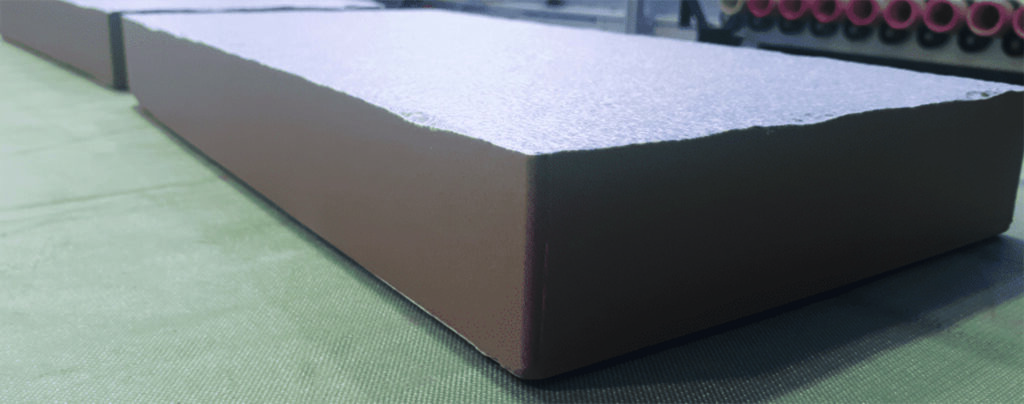

Italforni S.r.l., a company based in Formigine (MO) and operating from over 70 years, has embraced these aspects from the very beginning and it has become a point of reference for the realisation of innovative and sustainable thermic treatment plants. The company mission is to offer innovative technical solutions for tailor-made kilns for firing ceramic products (thickened tiles, vases, slabs, tableware, sanitary ware, bricks, roof-tiles, refractory products, and technic ceramics). Se possibile inserire in prossimità di questo paragrafo la foto “piastrella spessorata”. Italforni offers complete solutions for energy efficiency of production plants, accompanying the customer towards the best technological solution available for recovery energy and heat. Italforni, indeed, is always at forefront in design and development of systems, whose aim is a smart use of resources and offers different solutions that allow not only to optimise kiln energy consumption, but also to recovery energy where possible. Among the main solutions, there are:

– D.R.H.A & I.R.H.A. – Heat recovery from cooling zone of kiln allows to recover big volumes of high-temperature air (even over 300°C) without perturbing the inner space of kiln, so without damaging the material.

– ELECTRONIC COMBUSTION – the new combustion system is entirely managed electronically, and it allows a global energy saving up to 20%. The maximum performance is obtained when this system is put together with the heat recovery through D.R.H.A. & I.R.H.A., obtaining certified recovery up to 25%.

– AR VALVES – pneumatic control of air. It is an easy and economical solution that allows an energy saving up to 15%. It has been studied to work with air up to 200°C and allows a wide range regulation in the air/gas ratio, in order to adjust the burners according to the kiln zone they are.

The first move that Italforni suggests to the ceramic manufacturers is to adopt consolidated existing technologies, described above, remembering that the greener energy is the one saved. In some cases, they could bring a total consumption reduction of 45%. On the other hand, the European Green Deal has some very ambitious goals:

– no net emissions of greenhouse gases by 2050;

– economic growth decoupled from resource use.

On 2019, therefore, Italforni starts experimenting the hydrogen as alternative fuel to fossil gas, patenting in a short time a system for using big quantity of HYDROGEN in roller kiln for ceramic industry: HECO2®. Last June Italforni completed the first “Hydrogen Ready” plant for terracotta vases production. Thanks to this historic goal, the Company, settled in Formigine, is one of the main interlocutors for a real ecologic transition in the ceramic sector. The plant, recently realised, is entirely automated and permits the production of 50.000 vases per day with a gas consumption reduced of 30%. Se possibile inserire in prossimità di questo paragrafo la foto “impianto produzione vasi”

Today Italforni can offer, even on existing plants, hybrid solutions, able to use in a clever way the green electricity available, even in the form of hydrogen, together with methane gas or other fossil fuel.