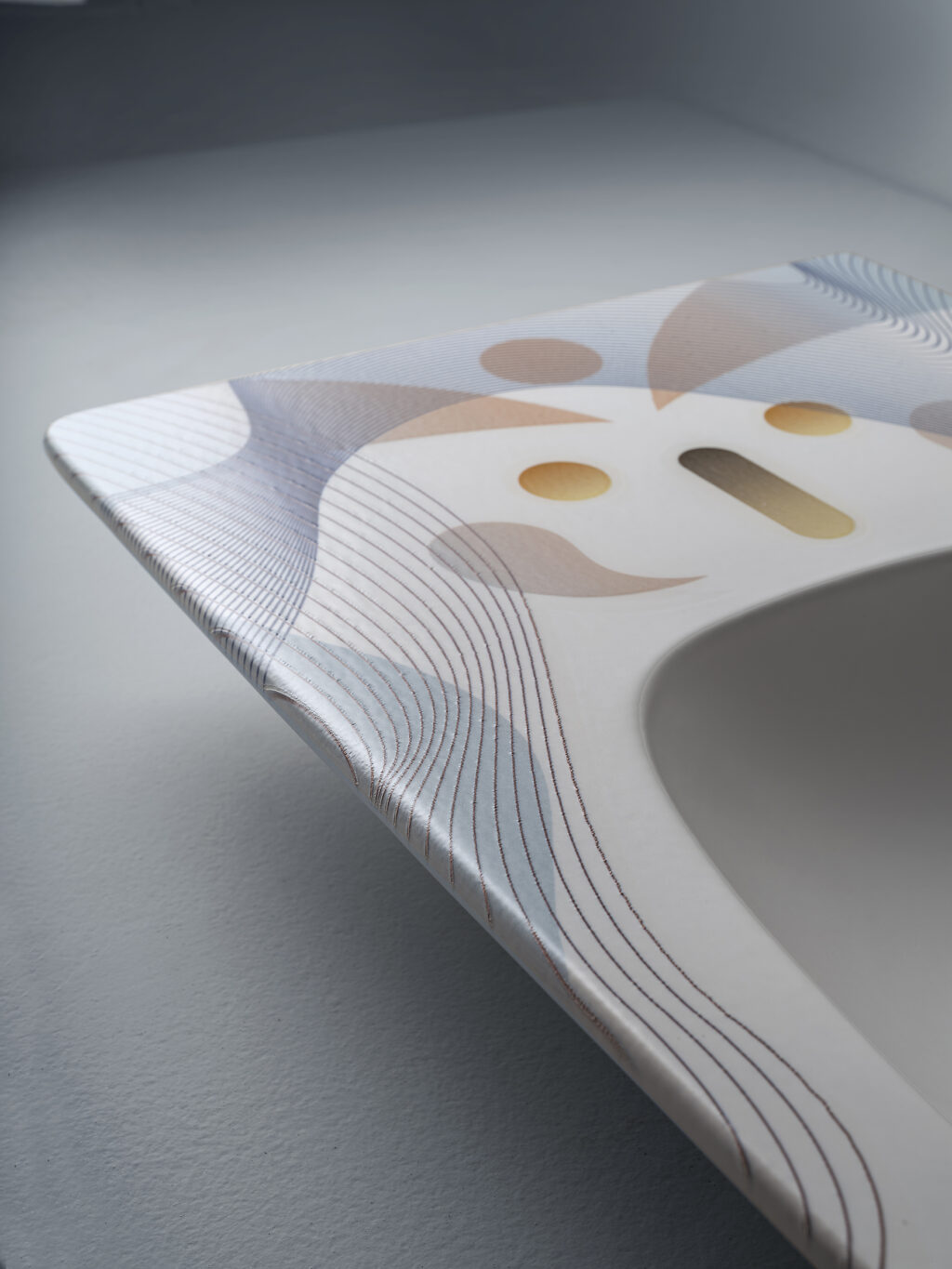

Shower trays and washbasins are now decorated with a DHD-D 908 digital printer. This is the first example of digital decoration being used on sanitaryware to create distinctive aesthetic and texturing effects. The collection was previewed at Cersaie, where it proved to be a hit with visitors

A company with 70 years of success and the undisputed leader in Italian high-quality designer sanitaryware, Ceramica Flaminia has now installed a new DHD-D 908 for digital applications on shower trays and washbasins. This is the first time digital decoration has been used on sanitaryware products: SACMI configured the printer by drawing on its extensive experience in the digital decoration of slabs and tiles.

“For us”, observes the CEO of Flaminia, Augusto Ciarrocchi, “this constitutes two major steps. First, it allows us to market ourselves with fresh, distinctive products. Second, it paves the way for a new approach to sanitaryware styling, which has, until now, focused on traditional glazes. We worked alongside the SACMI team to develop the solution and the resulting products, recently exhibited at the Cersaie fair, have yielded the hoped-for results.”

Ceramica Flaminia carried out the first printing tests with the new SACMI DHD-D 908 in mid-2022. The preliminary study was crucial: this sought to adapt the technique to the morphology of sanitaryware articles, leading to the development of specific methods and application solutions to allow printing on both unfired and fired glaze.

SACMI DHD digital printers, in fact, let you perform, depending on the required graphic design, one or more ‘single-pass’ applications. The outcome is high productivity, efficiency and unbeatable image definition.

But that’s not all. In addition to being able to control up to 8 colors via independent modules, the DHD has additional bars for the application of texturing inks and effects (glossy, opaque). This lets manufacturers move from a pure 2D effect to micro-textures and reliefs, enhancing the look and feel of the product.

The supplied solution is equipped with a conveyor system and an airless spray booth to apply the pre-decoration primer: “Another advantage of digital application”, continues CEO Ciarrocchi, “is that it allows for stylish sanitaryware decoration on small lots, quickly and economically, providing an effective response to demand for just-in-time production processes”.

With DHD, in fact, the ‘instructions’ to be transmitted to the independent modules consist of a pre-loaded graphics file that’s subsequently managed by inkjet heads with DOD (drop-on-demand) technology. The software maximizes flexibility in terms of both dimensions and design, from individual articles to control of complex graphics on multiple lots. Combined with the modular machine set-up, this delivers outstanding versatility to match all production requirements.

More generally, with this investment Flaminia is blazing a trail towards major innovation in the sanitaryware sector, enabling expansion and enrichment of the product range and cutting development times as part of a ‘total customization’ approach