The constant research into ceramic products, with added value and precious aesthetics, by the ceramic tile industry that targets evolved markets has led to the development and spreading of ceramic tiles whose surface, decorated with high thicknesses of glaze or micro-grains, is then honed or lapped.

If, on one hand, this mechanical process involving the removal of a superficial layer of vitrified glaze, makes the tile particularly glossy and satin, on the other hand, it decreases the resistance of tiles to staining, acids and affects the cleanability of the ceramic surface.

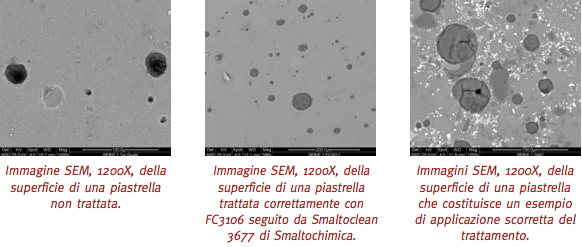

Honing and polishing processes remove the superficial layer of the glaze (or of the mix for technical porcelain stoneware tiles) causing the formation of open micro-porosity. In these micro-metric holes, the particles of staining agents deposit and make the surface difficult to clean when using water and common detergents.

Having, after years of experience, become the leader in traditional ceramic decoration, today Smaltochimica is able to offer a new product range for the final treatment of honed or polished technical porcelain stoneware tiles. This range has been developed in partnership with the Faculty of Chemistry at the University of Modena and Reggio Emilia.

These products are divided into various categories depending on the type of ceramic and production needs:

- Treatments for polished technical porcelain stoneware that mainly contain polymers able to create a film onto the ceramic piece, thus permeating porosity and guaranteeing resistance to stains and acids;

- Treatments for glazed and honed (or polished) porcelain stoneware that foresee the application of two products, the former needed to prepare the surface and the latter with the function of “pore-stopper” with anti-dirt, anti-staining and polishing characteristics.