LB HYBRID is the new solution for the ceramic body preparation designed to optimize production costs thanks to energy savings and in the perspective of total environmental sustainability.

This technology, in which dry grinding and wet grinding coexist, also guarantees maximum plant flexibility, adapting to every need of the manufacturer, and is patented.

In this new process, the powder obtained by dry grinding is homogenized with the barbottina obtained by wet grinding to obtain a micro granulate suitable for the pressing phase.

Micro granulation occurs by nucleation and increase of dry ground powder when, with appropriate nozzles, it is injected into the granulator, in certain powder-barbottina proportions and ensuring that the parts have the same composition. Granulation takes place inside the new continuous micro granulator HGT (Hybrid Granulation Technology). Subsequently, the micro granulate is returned to moisture values suitable for pressing.

Features and advantages

The LB Hybrid technology allows the optimization of production spaces, significantly reducing the overall dimensions, compared to traditional plants.

On an industrial level, the tests have shown that the behaviour of micro granulate obtained with LB Hybrid technology has the following features:

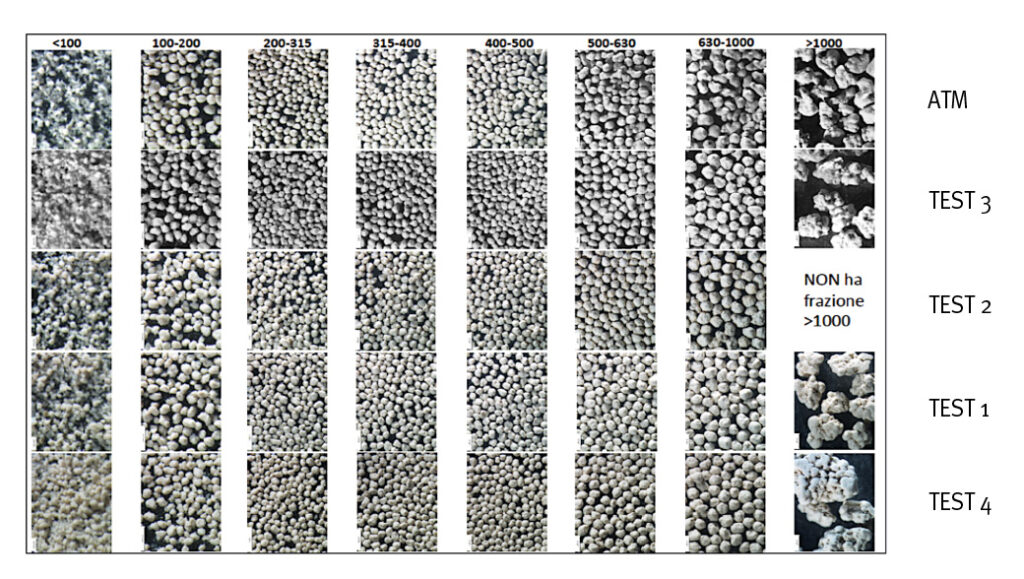

• grain with smoothness equivalent to the one from standard technology;

• possibility of creating formats of any size and thickness with all the forming technologies currently on the market;

• finished products in porcelain stoneware complying with the standards;

• controlled grading curve;

• surface of high quality ceramic products.

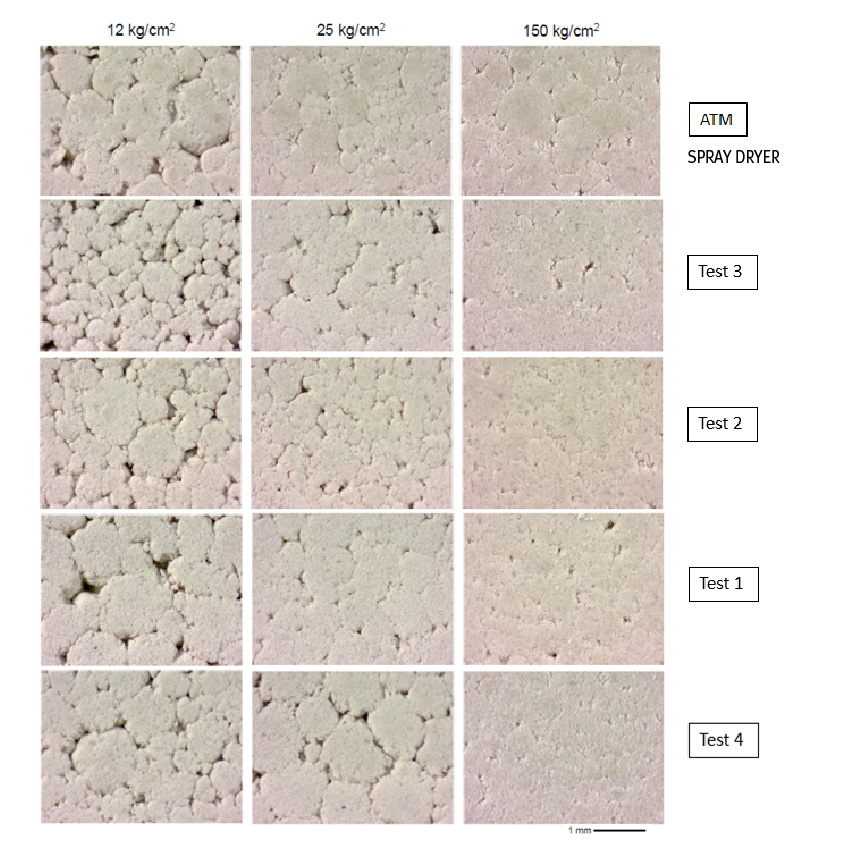

The surface of the tiles obtained with micro granulate produced with LB HYBRID technology has shown excellent characteristics compatible with all decoration systems (fig. 2).

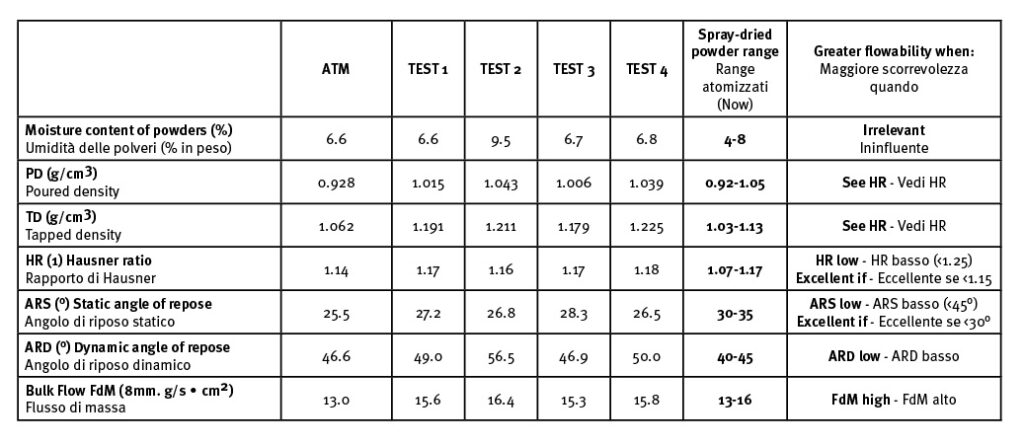

From the technological point of view, the characteristics of the microgranules LB HYBRID have features similar to those from standard technology (tab. 1).

Compared to a standard body preparation process, LB HYBRID technology saves 65% of thermal energy and 70% of water and reduces atmospheric emissions by 65%. Assuming an annual production of 5,000,000 m2 of 10 mm thick tiles, with LB HYBRID there are lower CO2 emissions equal to 6,000,000 kg/year and a water saving of 30,000,000 litres/year, considering an average moisture content of 10,5% and a moisture of the barbottina equal to 32%.