At the heart of technological evolution in the ceramic industry, a new frontier of innovation is emerging: EDGE, the inkjet printer specifically designed for the direct edge decoration of ceramic skirting boards. Previewed during Tecna 2024 exhibition, EDGE represents unique system engineered to meet the market’s evolving needs with efficiency, precision, and sustainability and responds to the growing demand for advanced customization, high-end decorative detail, and reduced environmental impact.

In today’s highly competitive ceramic production landscape, edge decoration of skirting boards is often overlooked—yet it is essential for achieving visual continuity and flawless aesthetic results in the finished product. With EDGE, this stage of the production process is completely redefined thanks to a radically innovative and fully automated approach, combining next-generation inkjet technology, advanced materials, and an optimized industrial workflow.

At the Core: Direct Edge Printing with Round Drop Inkjet Technology

EDGE features a cutting-edge direct-to-edge printing system based on the brand-new Round Drop Inkjet Technology platform. This proprietary technology enables the controlled deposition of perfectly spherical ink droplets, ensuring uniform coverage—even on slightly uneven or irregular surfaces. The result is exceptional precision in detailing and decorative continuity between the front surface and the edge of the skirting board, delivering an unprecedented material and chromatic seamlessness.

Water-Based Inks: Performance Meets Eco-Compatibility

One of EDGE’s most groundbreaking features is its water-based ink system, enhanced with a high-performance nanopolymer that deeply penetrates the ceramic surface and bonds securely through a dual-firing process. This proprietary formulation ensures outstanding resistance to abrasion and everyday chemicals—such as alkaline cleaners and mild solvents—while also being a strategically sustainable choice. The complete absence of volatile organic compounds (VOCs) makes the entire process safer for the environment and for production personnel.

EDGEwave Oven: Smart Low-Energy Curing

The ink drying and fixing process is managed by the exclusive EDGEwave low-temperature oven—a compact yet highly efficient unit that uses variably modulated ionic waves to polymerize the ink with significantly lower energy consumption than traditional gas-fired kilns. This innovative system not only ensures perfect drying but also preserves the original brilliance and chromatic depth of the printed decoration.

Before entering the oven, an intermediate stage employs FULVIUS infrared lamps, designed to fix the ink at 350°C in ultra-fast cycles. This step is crucial to ensuring print stability and preventing undesirable effects such as meniscus formation or color bleeding, thereby ensuring a consistently sharp and uniform definition.

A Complete Color System for Total Creative Freedom

EDGE operates with a 6-color printing system, including standard CMYK, a high-opacity white channel, and a special Glossy channel for controlling surface finish. The inclusion of white ink enables printing on dark substrates while maintaining vividness and saturation through highly precise overprinting. The Glossy channel, in turn, allows for dynamic modulation of surface gloss, adding visual depth and tactile variation to the final product.

This color flexibility translates into unprecedented creative freedom, making EDGE the ideal tool for both high-volume production and short, high-value-added print runs.

Optimized Workflow: From Loading to Packaging, Without Interruption

The entire production flow is engineered for maximum operational efficiency. Skirting boards are batch-loaded directly onto the printer’s motorized conveyor belt, powered by a brushless motor, with a print width of 70 cm that allows up to 70 pieces per cycle. Graphic files are managed via the powerful DINA RIP software, which includes advanced features such as automatic de-tonalization and continuous decoration alignment between front and edge. This ensures a perfectly harmonious result, even for complex graphics and textured designs.

A high-resolution, intuitive, and customizable touchscreen interface allows real-time monitoring of all printing parameters, material status, and system adjustments.

Millimetric Precision with AXXY Height Control Technology

Another standout feature of EDGE is the integration of AXXY, an active height-reading module that ensures consistent distance between the printheads and the skirting surface at every point of the cycle. This is essential for maintaining print quality on pieces with slight dimensional variations, ensuring perfect focus and consistent inkjet deposition.

Industrial Performance: Up to 2,000 Pieces/Hour at 1280 dpi

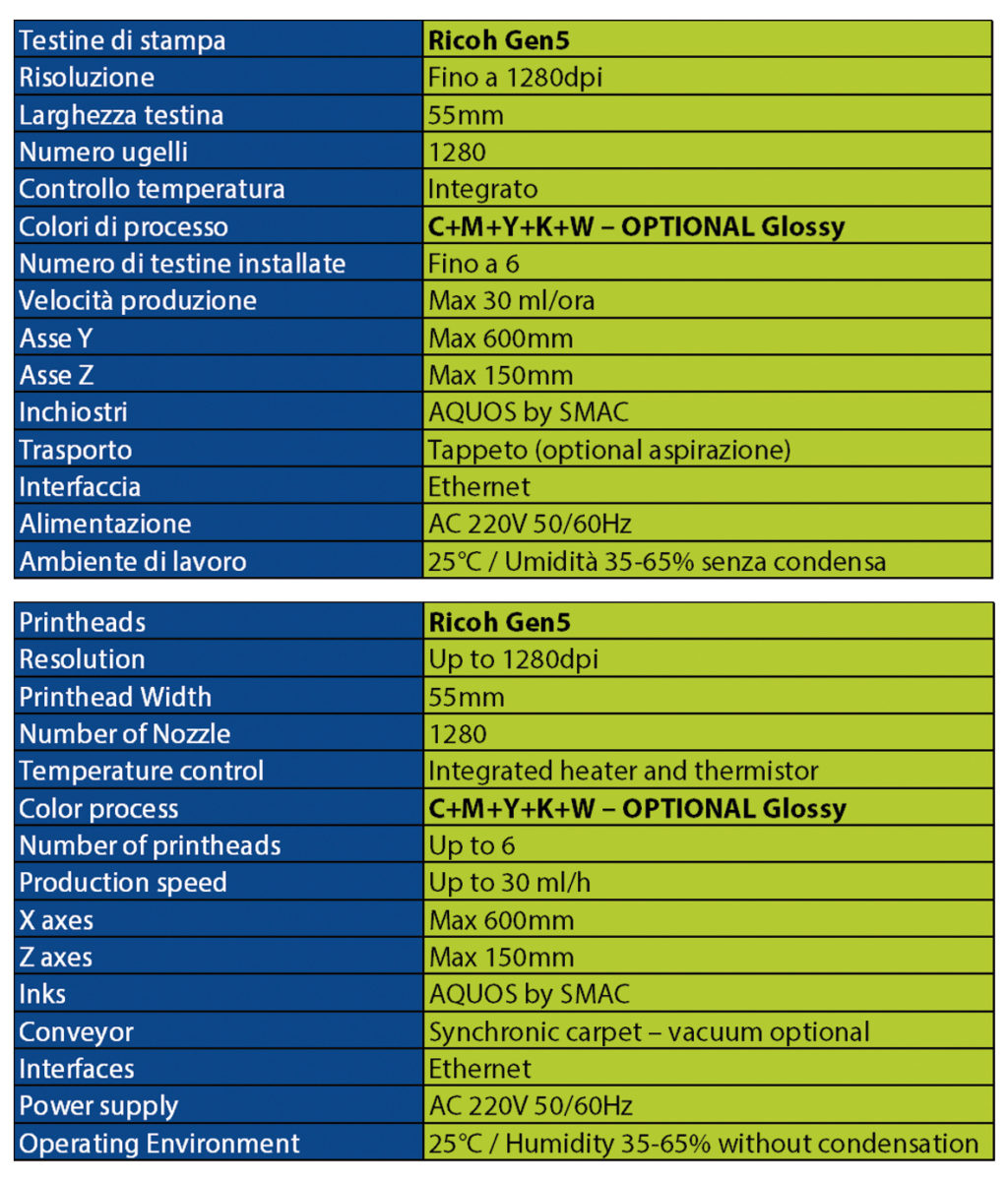

Despite its outstanding visual output, EDGE also delivers top-tier industrial productivity. The system can print up to 2,000 skirting boards per hour, with a maximum resolution of 1280 dpi, thanks to its use of Ricoh Gen5 printheads—renowned for their reliability, longevity, and ability to render ultra-fine details with consistently vibrant colors.

EDGE: A Strategic Investment in the Future of Ceramics

In an industrial context increasingly focused on customization, speed-to-market, and sustainability, EDGE represents a forward-looking strategic investment. The integration of advanced technologies, innovative materials, and a fully digitalized production process allows for significant reductions in operating costs, energy consumption, and production time, while dramatically enhancing perceived quality and product value.

With EDGE, edge decoration is no longer a secondary detail, but becomes a central element of ceramic design, actively shaping new trends and standards in porcelain stoneware coverings and accessories.

Digital printing for the ceramic industry enters a new era with EDGE: a comprehensive, scalable, and sustainable solution, designed to elevate every detail of ceramic products—even the most hidden edges. A technology that speaks the language of production excellence, continuous innovation, and environmental responsibility.

For those who look to the future with strategic vision, EDGE is not just a printer—it’s the new benchmark for the ceramic industry